Royal Mint unveils new e-waste gold extracting factory

The Royal Mint has announced the launch of a new factory which will extract gold from electronic waste.

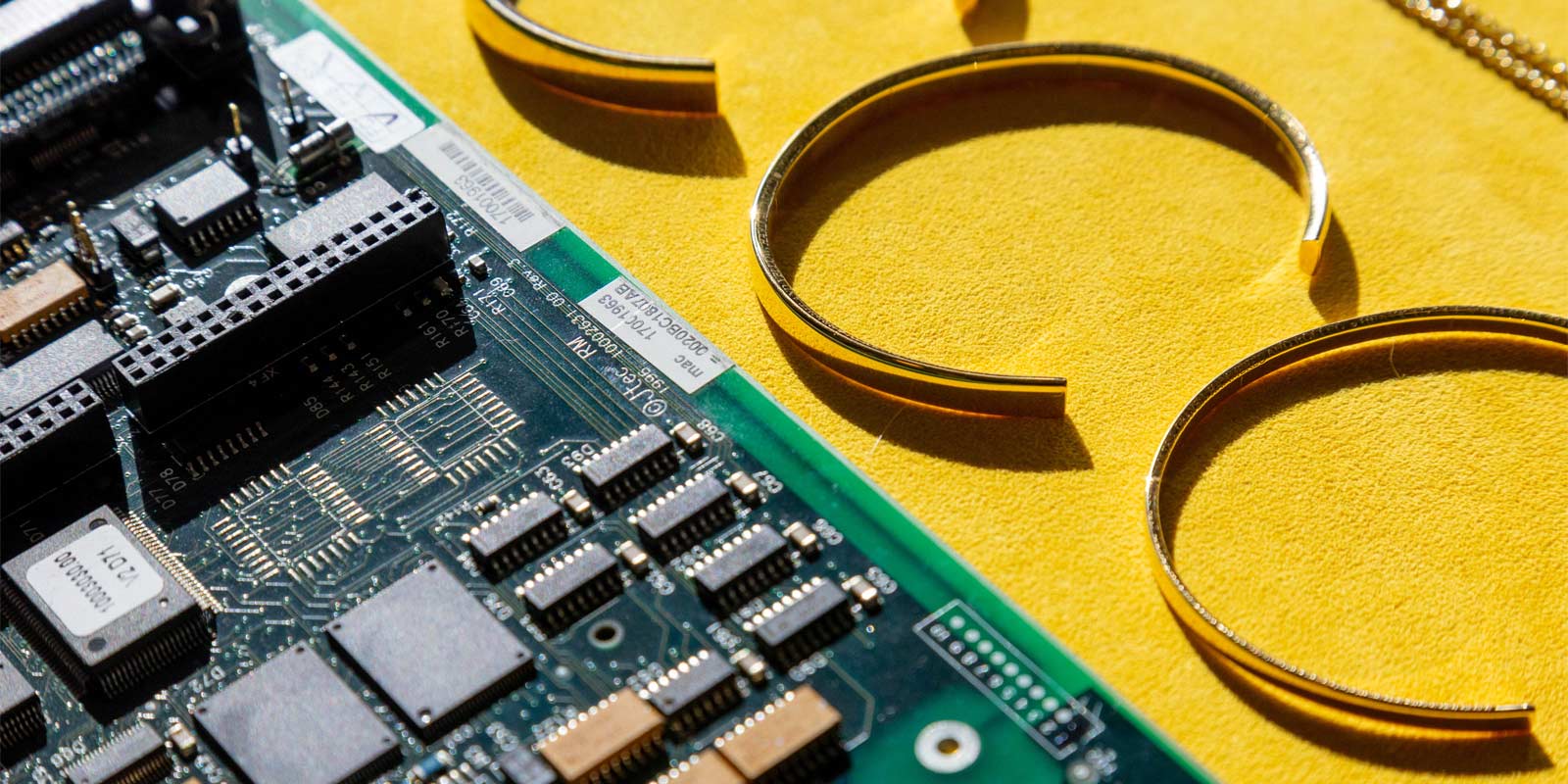

Located in south Wales, the 3,700 sqm facility uses chemistry from Canadian clean tech company Excir to extract gold from printed circuit boards (PCBs).

The factory has scaled the innovative technology from laboratory to an industrial level for the first time and has the capacity to process up to 4,000 tonnes of PCBs from e-waste every year.

The Royal Mint has also been actively engaging with major industry bodies to help produce the first standard by the International Organization for Standardisation (ISO) for the definition of recycled gold,

Advertisement

Recovered gold is already being used in the luxury jewellery collection, 886 by The Royal Mint.

Anne Jessopp, chief executive at The Royal Mint, said: “The Royal Mint is transforming for the future, and the opening of our Precious Metals Recovery factory marks a pivotal step in our journey.

“We are not only preserving finite precious metals for future generations, but we are also preserving the expert craftmanship The Royal Mint is famous for by creating new jobs and reskilling opportunities for our employees. We have ambitious plans, and I am proud that we are safeguarding The Royal Mint for another 1,100 years.”

Sean Millard, chief growth officer at The Royal Mint, said: “The factory underpins our commitment to using sustainable precious metals and providing a new source of high quality, recovered gold.

“It allows us to reduce our reliance on mined materials and is another example of how we’re working to decarbonise our operations. Our commitment to growth, innovation and circular economy principles shapes an exciting and more sustainable future for The Royal Mint, our people and our communities.”

COMMENTS